DOSING SYSTEMS

The DOSERAY micro-ingredient dosing system is available with

up to 34 dosing cells, each with a dosing screw. Rotary

discharge equipment can be provided as an option for products

with poor flow characteristics.

The dosing screws

discharge into one, two or three weighers, depending on the

total number of ingredients. The weighers can be installed at

different levels and work simultaneously. In the set-up with

three weighers, the top weigher has a net weighing capacity of 5

kg, the middle weigher 10 kg and the bottom weigher 50 kg.

They are accurate to 5, 10 and 50 g respectively.

The

weigher has two flexibel rotary valves with a flexibel

connection which acts as an airlock. The seperate bins are made

of stainless -or mild steel and has a special inner layer for

food products. The dosing screws can have different diameters.

Larger screw are provided with a smaller screw underneath to

achieve optimum accuracy.

In modern feed plants can the

micro-ingredient dosing system work inline with the central

chargesystem.

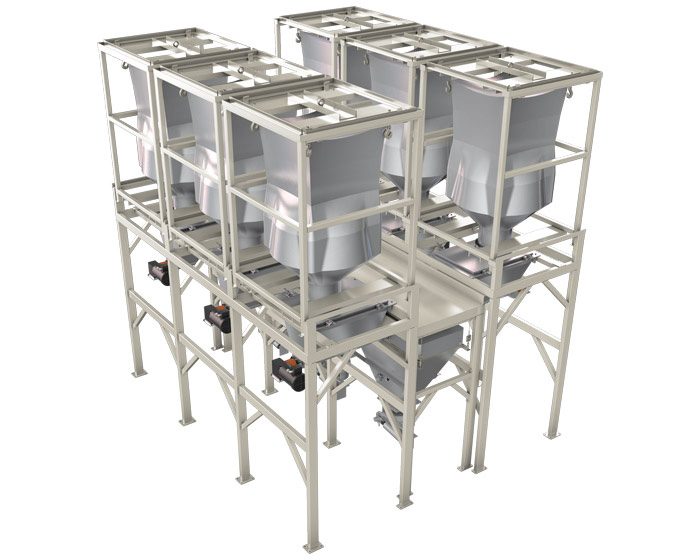

Bulk Bag MinorScale weighing systems provide accurate dosing of minor ingredients into your batching system. Our two available configurations — traditional and linear — offer accuracy, volumetric capacity and speed. These scales use bulk storage bags as ingredient bins that are supported over the scale on removable rack frames. Our team can help determine the appropriate scale system solution to optimize your batching performance.

PDF

brochure

process

.

- RDOSERAY micro-ingredient dosing systems can be designed

to include up to 34 dosing cells, each equipped with a screw

feeder. Rotary discharge equipment can be provided for poorly

flowing products as an option.

The screw feeders discharge into one, two or three weighers, depending on the total number of components. The weighers can be set up on various levels and work simultaneously. In the set-up with three weighers, the top weigher has a net weighing capacity of 5 kg, the middle one 10 kg and the bottom one 50 kg. They are accurate to 5, 10 and 50 g respectively.

The micro-ingredient dosing systems have two flexible rotary valves with a flexible connection which acts as an airlock. The separate bins are made of stainless -or mild steel and have a special inner layer for food products. The dosing screws can have different diameters. A larger screw is provided with a smaller screw underneath to achieve optimum accuracy.

In modern feed plants can the micro-ingredient dosing system work inline with the central charge system.

Features

High accuracy in weighing

Flexibele formulation

Fully automatic controlled proces

Dustproof design

The storage bunkers for the components are made from stainless steel or steel ST37 with a food-quality internal coating. The screw feeders may vary in diameter, with the larger ones having a fine-dosing feeder underneath for maximum accuracy.

In modern animal-feed installations the micro-ingredient dosing often operates in-line with the central batch system. Depending on the size of the batch it may be a good idea to homogenise the dosed micro-ingredients first with a carrier on a separate mixer before adding them to the main batch.