Functions And Operating Modes Of a Rotary Valve

Generally a rotary valve has two basic functions: Discharging

and metering. Both the functions have

an additional task to establish an air lock point between two

sections of the system. Absolute air lock is

however not possible at the given pressure difference. The flow of

the leakage air can only be minimised.

Discharge

The basic function of pure discharging

is executed by the well-known basic rotary valve: In the

housing the rotor is revolving by constant speed. Due to gravity the

product comes out fromthe container or the hopper from the top

and falls in the chambers of the rotor. Due to the

revolving rotor the product is transported to the discharge

opening, from where it again moves down by

gravity. The rotary valve itself does not affect the flow capacity

of bulk solids. It depends on the chamber

volume, filling ratio and rotation speed.

Metering

The rotary valve for metering is

characterised by a variable speed, e.g. using a variable-pitch

geared motor or a frequency converter drive. The metering is purely

volumetric in such a case: A

specific volumetric flow per time

unit is set as the desired value in dm ³/s or m³/h. It is however

not measured so that there is an undefined

deviation between the desired and actual values.

The mass flow capacity is not measured and regulated, and therefore

the term, "metering" is actually incorrect in the

strict sense; a constant and reproducible volumetric flow can

however be set. The condition is, that

a) the density of

bulk solids is always constant,

b) the rotor is always fed with

the same filling ratio. This can be achieved, e.g. using an

agitator or a pneumatic discharge aid in the pre-hopper over the

rotary valve,

c) the chambers are emptied completely

Bulk Solids

Grains

Powder

Fine

powder

Grease (only with special model)

Granules

Application procedures

Discharging

Metering

Feeding

Protective System

Advantages:

• Space-saving, less installation height due to

built-in conveying air

connections in the housing

• Large

capacity range

• High operational safety due to sturdy design and

cleaning effect by

blowing out the rotor chambers

•

Cost-effective owing to low installation investment

• Low

maintenance due to simple assembly

• Less leakage air

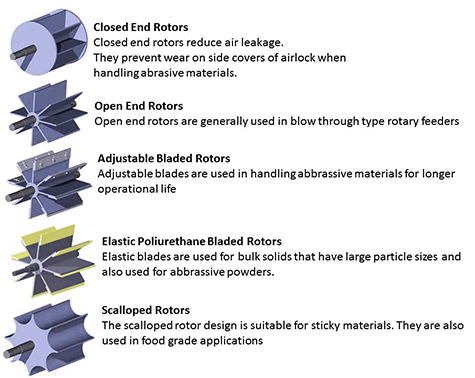

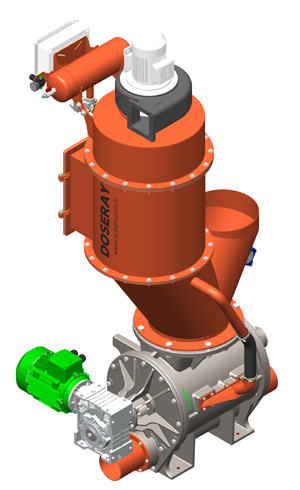

ROTARY VALVE ROTOR TYPES

-

- Rotary Valve - Ailocks-Star Feeder internal

Rotors have options such as blade, rounded type, adjusted blade

type, stripper and polyamide. Discharging

valve for fine and coarse-grained products

Max. capacity through ideal ratio of rotor volume and inlet cross section

Special inlet geometry purpose-built for gentle product handling

With feeding show also suitable for feeding bulk materials into pneumatic conveying systems at up to 1.5 barg (21 psi) -

PDF

brochure

ROTARY VALVe characterıstıcs

• Sizes (entry): Æ 175, 200, 250, 300 mm

• Delivery rate: 0.3 - 50 m³/h

• Pressure shock resistant and

flame penetration resistant up to 10 bar (overpressure) with a

DMT certificate

• 1) The housing contains: horizontal conveying

pipe with a connecting flange for a

pneumatic conveying

pipeline

• 2) Emptying by blowing out the rotor chambers

horizontally using conveying air

• 3) Robust cast housing made

of GG, GS, 1.4308, 1.4408

• 4) Pressure-tight shaft seal with

radial shaft sealing rings and sealing air connection

• 5)

Integrated leakage air dissipation

• 6) External bearing

•

7) Chain drive with a geared motor attached laterally

Drop Thru Rotary Valve Models

- 120mm DRAW- cad

- 180mm DRAW-cad

- 200mm DRAW valve -cad

- 220mm DRAW-Cad -cad

- 320mm Draw-cad

- 320mm Long Type Draw -cad

- 350mm Draw-cad

- 450mm Draw-cad

Blow Thru Rotary Valve Models

While pneumatic transport processes differ according to the phases, it may also diffrent in the same phase. Low pressure, that is dilute phase transfer, can be categorized under 2 classes, namely vacuum and pressure. This classification shows, even slightly, differences in the rotary valve - airlocks. Consequently, we perform manufactures according to the air locks to be used on the vacuum and pressure line.

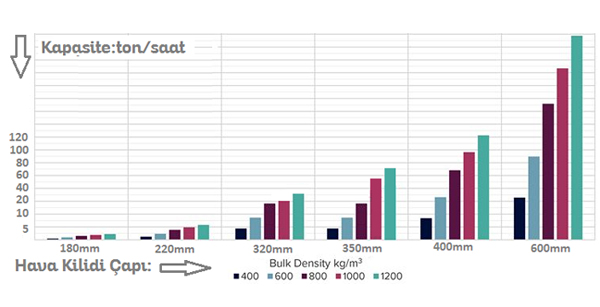

ROTARY VALVE capacıty

Rotary airlock feeders have wide application in industry wherever dry

free-flowing

powders, granules, crystals, or pellets are used.

Typical materials include: cement,

ore, sugar, minerals, grains,

plastics, dust, fly ash, flour, gypsum, lime, coffee,

cereals,

pharmaceuticals, etc...

- Lebels: rotary valve, rotary airlock, airlock valve, rotary feeder, blow through rotary valve, flow through airlock, silo discharge, cyclone discharge, dust collection, pneumatic conveying, rotary air lock valve, rotary valve producer, rotary valve price, rotary valve tecnichal draw