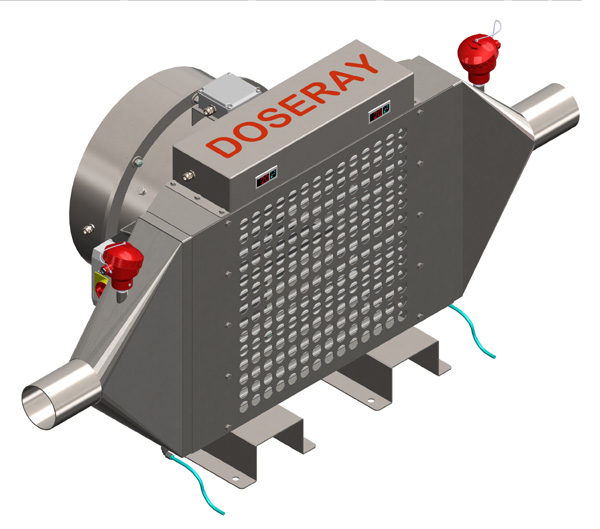

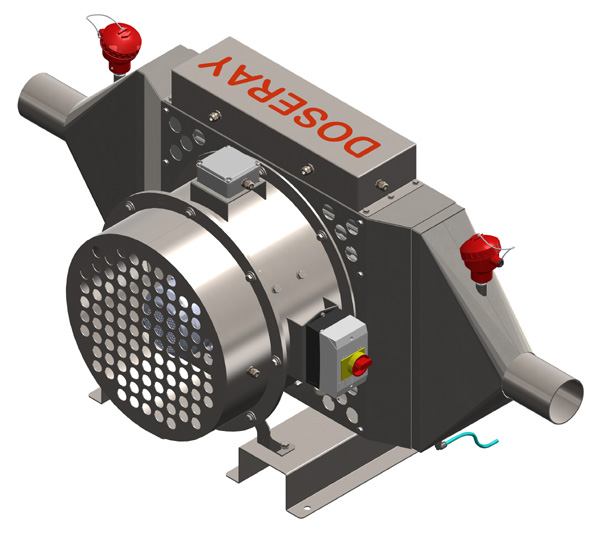

AIR COOLING AND DRYING UNITS

Dehumidifiers-Coolers:

This equipment change atmospheric conditions of the air used in the

processes. When performing pneumatic transport in some processes,

the air delivered by the blower may reach to 65-70oC, possibly

making change in the characteristics of the raw material to be

transported. For this reason, complex equipment cooling or removing

moisture of the air are required.

With our air-conditioning systems, we can cover virtually all

quantities of air, temperature and dew point ranges.

Our

customised devices are primarily used in the process air area for

use wherever conventional devices in the field of technical building

equipment cannot provide satisfactory solutions. In addition to a

wide service range, our air-conditioning units can take into

consideration customer-specific factory standards or specific

hygiene requirements.

We can already cover a wide range of

services with our standardised designs, the

DOSERAY-COOLER process air coolers. The proven and

advanced devices offer an ideal price-performance ratio, especially

for the pneumatic transportation of bulk materials.

What distinguishes the series process air cooler from other coolers?

TheDOSERAY series use an optimised air cooler, which has

a negligible loss of pressure in pneumatic applications. The design

is suitable for both atmospheric and pressure-resistant processes.

The heat exchanger has an energy-efficient design.

COOLING TECHNOLOGY

COOLING TECHNOLOGY

- Due to the adiabatic compression high heat flow rates are to

be conveyed and extracted, in particular, when the process air

cooler has been arranged on the pressure side, so that the

process air is first precooled with the ambient air to save

energy before it is conveyed to the main cooler. This precooling

releases the main cooler and offers the plant user interesting

cash savings. Our economic precoolers of the

DOSERAY series are suitable for this purpose as they

operate as cross flow heat exchangers and are equipped with

their own ventilation blower thus ensuring efficient precooling

of the process air. Of course this ventilation unit can be

speed-controlled if this is required in the application to

obtain precise temperatures.

benefıts

INot only humidity is extracted from the air, but also undesired by-products are extracted from the air /gas when the temperature falls below the dew point. This procedural method known as cold trap and/or gas washer is used in many procedural applications and can be realised with our technology.

CONVEYING-COOLING

fer

- Lebels: blower air cooler, air to air cooler, pneumatic conveying air cooler, blower air cooler, pneumatic conveying flour cooling, pneumatic conveyinf sugar cooling.