sılo dıscharge solutıons

Engineered mass flow bin designs often result in tall steep bins. Successful mass flow is highly dependent on the ability to maintain consistent material properties such as moisture, particle size and consolidation time. Variations in these properties can drastically alter flow.

The Transmin bin activator range offers a cost effective and

reliable alternative to mass flow hopper designs. The bin activator

is able to overcome the problems of material packing in the

converging lower cone of the bin (a common cause of flow problems)

and will encourage an even, flat withdrawal of product from the

storage silo.

This has the added benefit of minimising ‘classification’ of product created by funnel flow discharge and effectively re-mixes fines with larger particles in a similar distribution to the original mix.

Bin Activators are easily installed to existing

silos as cheap alternative solution for flow problems

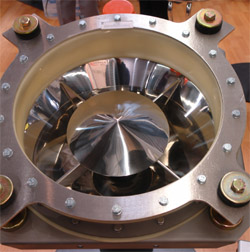

Custom Engineered Designs bin Activators

For highly specialised applications, Transmin has the ability to supply custom machines, taking careful consideration of the duty requirements and material to be handled.

PDF

brochure

- Range: Ø 600mm (23 in) ~ 2,100mm (7 ft)

- Material: carbon steel, 304L / 316L stainless steel

- Robust, compact design

- Range of seals (gaskets) including FDA-approved, food-grade version and high-temperature version

- Wide range of baffle plates in accordance with application

Minimal Maintenance: DOSERAY Bin Activators require minimal maintenance due to essential components being designed to successfully contend with the vibratory service requirements. The result is the longest possible service life with minimal or virtually no maintenance attention. The only “preventive” maintenance required is the occasional greasing of the vibratory motor.

Benefits

Low power requirement

Extra-durable suspensions and seal (gasket)

70% fewer welds than with traditional bin activators

Seamless heavy-duty activator cone

Options

Suspensions suitable for installation on aluminium silos

Vast range of electric motovibrators (see OLI motovibrators)

Additional fluidisation/aeration system

Outlet spout with emergency slide gate

Negative pressure version availableeck Ladder, Lower-Upper Manhole, Filling Pipe Inlet Nozzles and Inlet with Level Sensor Inlet are optionally available

- Lebels: rotary valve, big bag unloader,bigbag discharger, bin activator, bin activators, silo discharge , bin activator manufacture